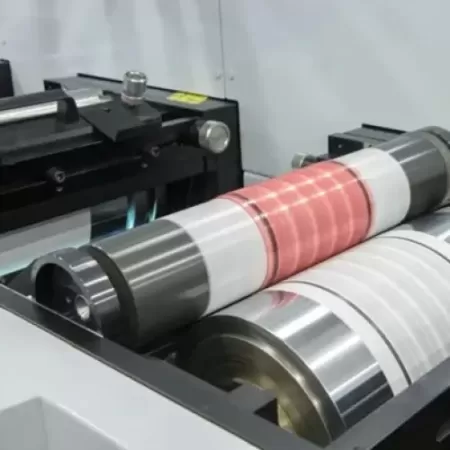

Adhesives

At adhesives+coatings we have a mission to make the adhesive & sealant market more sustainable.

Are you looking for a new, unique adhesive or sealant for your industrial project?

We help industrial end-users innovate by delivering a greener, customised adhesive that has the right properties for their production process, and don’t leave a footprint. For free!

Upon receipt of your request, we’ll work with you on analysing your specific adhesive needs. We help you identify the ideal characteristics of your chosen adhesive and guide you through the process of finding and using your new adhesive. We’ll make sure to get the full picture, including technical specifications, application process, volume, etc. Once we have the most important facts, we’ll start our search. As independent platform we’ll identify the best manufacturer for your project via our world-wide network. By connecting you with that manufacturer we supply that highest-quality niche adhesive!

Our specialisms

Are you looking for a unique, environmentally friendly adhesive, sealant, or coating? We can always identify a product that meets your requirements!

An adhesives question?

Latest articles

How can we help you?

The rapid disruption our industry faces, present many challenges for the majority of our current market.

At adhesives+coatings we see it as our mission to make the market and industry more sustainable. We help companies to innovate by delivering greener, customised adhesives or coatings for their projects. Typically these are unique, niche products that do not leave a footprint.