Eco-friendly bottle wraps

As a producer of alcoholic (and non-alcoholic) beverages, you use bottle wraps for a number of reasons. But at least not because it is such an eco-friendly addition. Because aluminium wraps for glass bottles are definitely not.

Looking for a more eco-friendly alternative?

BOTTLE WRAPS

As a producer of beer, champagne or other alcoholic and non-alcoholic beverages, you use aluminum bottle wraps for functional reasons. But also to give the bottle a luxurious look. The wrap is essential to give your product a good brand experience.

The fact that wraps are not always practical and require a lot of cost and effort, including the recycling process, is why many manufacturers take them for granted. You probably do, too. You may also be considering the environmental impact of aluminum bottle wraps. But switching to an alternative? Then that alternative needs to be very good to change the current process.

adhesives+coatings has found the perfect alternative for any producer of beverages in glass bottles. Not only as an alternative to aluminum bottle wrapping and the environmentally unfriendly adhesives used, but also for application to new products.

THE USE OF BOTTLE WRAPS

Aluminum bottle wraps, who doesn’t know them? A special beer or champagne bottle with a nice wrap over the cap that really makes it pop. You peel it off and open it! Ready to enjoy that special drink. That experience, surely that is the ultimate finish to the product.

Aluminum bottle wraps are therefore also valuable additions for many manufacturers. It completes the product. No wonder marketers love the use of bottle wraps. For product recognition, but also to distinguish different types of beverages from each other. It is part of the branding of the product.

In addition to the luxurious look that the wrap gives to the bottle, they are also designed for functional reasons:

- For protection of the bottle cap and bottle mouth, against dirt and bacteria

- Also for protection of the bottle when a cork and cork binder is used

- To keep the cap clean (especially important with small bottles where people do not use glasses)

- helps to keep bottles cold, which helps to better preserve the liquid and preserves the taste

The bottle wraps can therefore be found on bottles of all shapes and sizes, such as: beer bottles, champaign bottles, bottles with liquors, whiskey bottles and wine bottles.

Aluminum wraps are thus not only aesthetically pleasing, but also provide a valuable functional benefit. Why shouldn’t every manufacturer use them?

DISADVANTAGES OF WRAPS FOR GLASS BOTTLES

Bottle wraps are not used on every bottle for a reason. The use of aluminum bottle wraps also brings disadvantages.

First, the cost. For a luxury product, or if a wrap is functionally necessary (as with cork threads), it is fine to pass the cost on to the consumer. The cost of aluminum wraps is not only the processing of the wraps in the manufacturing process, but also the aluminum and the adhesive itself. Aluminum is an expensive product.

Wraps also often require special recycling facilities in the bottle recycling process, especially beer bottles. In addition to removing the aluminum from the bottle, the adhesive used to hold the aluminum foil in place can be difficult to remove and recycle.

Finally, aluminum wraps have an impact on the environment. The production of aluminum is harmful to the environment. But the recycling process also leaves aluminum scraps, often with glue and color residue. This makes it difficult to reuse the residual waste.

THE ALTERNATIVE TO ALUMINUM BOTTLE WRAPS AND ADHESIVE USED

We have seen that using bottle wraps has both advantages and disadvantages. How cool would it be if you, as a producer, could still have all the advantages of wraps without having to deal with the disadvantages?

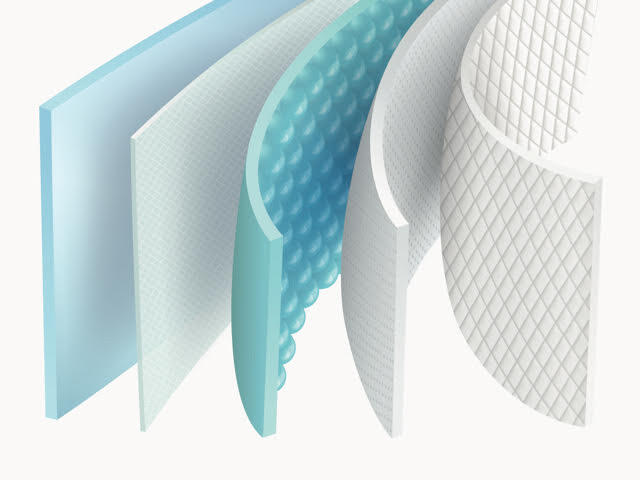

We found a product that has all the advantages, but takes the disadvantages off the table once and for all. An environmentally friendly cold glue that is suitable for aluminum wraps, but also allows even the aluminum to be substituted for paper. In this way, you make the whole wrap environmentally friendly and recyclable. Besides from these advantages, paper has more opportunities for prints and colors. This adds even more marketing value to the bottle wrap.

This cold glue for bottle wraps has the following advantages:

- It is eco-friendly.

- The cold glue dries quickly .

- Keeps the wrap in the right place (does what it needs to do).

- The wrap is still easy to take off with your hands for consumption.

- It will not release if the bottle gets wet or is stored in extreme conditions, such as very cold or hot temperatures. For example, in the freezer or in direct sunlight.

- Is easy to remove in recycling processes (when the bottles are washed/heated up to 60 degrees or more for cleaning).

THIS ALTERNATIVE IS EASY TO INTEGRATE IN CURRENT PRODUCTION PROCESSES

These are very nice benefits! But as a manufacturer, it is only feasible if the main production process does not have to be changed. Ultimately, you have to weigh the costs against the benefits. This was also taken into consideration. The alternative adhesive is a cold glue. This probably doesn’t sound like music to your ears because you assume that the drying time is longer, and therefore the production speed is lower. But this is a false assumption. The adhesive is designed to dry very quickly and to have a fast initial tack.

In addition, the adhesive has several other advantages:

- Less glue is needed then current glues, it saves glue

- Lowers production costs

- It is easier to recycle, just put it in the recycling bin

- More environmentally friendly

If you also choose to switch from aluminum to paper bottle wraps, which is almost indistinguishable from aluminum, you have many more options to give them the brand look you want.

WANT TO TEST THE ECO-FRIENDLY ALTERNATIVE TO ALUMINUM BOTTLE WRAPS?

Are you a beverage producer and would you like to test whether the alternative adhesive, and possibly the paper variant, adds enough value for you? We would love to help you make your process more sustainable! Feel free to contact us to discuss the possibilities.

What solution are you looking for?

We are specialized in the packaging and paper. Need the best products or advice? Then please leave your details and we will get in touch.