Acid resistant coating for concrete

Concrete in industrial environments

Concrete is a commonly used material in industrial environments due to its durability, strength, and ability to withstand heavy loads. In addition, concrete is often the material of choice because of its relatively low cost. If a structure is needed that covers a large area, the choice of concrete is quickly made. Concrete is commonly used in floors and walls, but also for example in:

Manure cellars and other agricultural applications

Water treatment plants and concrete pipes for sewage disposal

Storage tanks

Battery rooms

Reservoirs

Cellars

Concrete is used in many industrial environments where it may come into contact with various concrete-aggravating liquids.

Concrete and acid resistancy

When concrete comes into contact with acids, it can lead to a chemical reaction: an alkali-silici reaction. A harmful chemical reaction in which the concrete reacts with silicates from the environment. Acid attack occurs because concrete is an alkaline material, and when it comes into contact with an acidic substance, the pH of the concrete drops. As a result, the chemical bonds that hold the concrete together weakens. It starts to absorb water and expands. It leads to corrosion of the concrete, resulting in cracks and concrete rot that weakens the construction and reduce its lifespan.

Different kinds of acids that attack concrete

Some specific forms of acid attack on concrete are distinguished:

Biogenic sulphuric acid

Acid attack of the concrete surface by sulfuric acid produced by bacterial conversion of sulfides to sulfuric acid;

Microbiological nitric acid

This form of acid attack is characterized by sanding and the formation of loose shells on the concrete surface by nitric acid-forming bacteria. Occurs the interior walls of cooling towers for example.

Adhesion by salt, minerals and strong acids

This is the dissolution of cement stone as in acid attack. This attack occurs particularly in fertilizer storage (ammonium salt) and seawater attack (magnesium salt).

Soft water

Soft water can dissolve lime. A concrete surface can be damaged if it is in contact with soft water that is constantly changing. This attack mechanism is similar to acid attack.

Acid resistant coating

To protect concrete from acids in its environment, an acid resistant coating is the best solution. A good acid resistant coating can be applied to all types of concrete, regardless of the porosity of the concrete. The coating should deal with the attack of acids, sulfates and other salts as well as the corrosion of reinforcing steel and non-ferrous metals. Which acid resistant coating is best for your situation, depends on the types of acid the concrete comes in to contact with. The table below shows all the coating types along with their overall resistance and the various acids they are not resistant to.

Epoxy coating

Degree of acid resistance: Medium Not resistant against: Sulfuric an nitric acids

Epoxy novalac coating

Degree of acid resistance: Very high Resistant to all types of acids

Polyurethane coating

Degree of acid resistance: Medium Not resistant against: Aggressive acids

Choosing the right acid resistant coating for concrete

When it comes to making a decision in which type of coating is best for your situation, depends on several factors. For example:

What specific acids the coating needs to be resistant to

The concentration of the acids

The temperature of the area where the exposure will occur

What other properties, in addition to acid resistance, the coating should provide in

The coatings market is changing rapidly. New coatings that are more acid resistant and better for the environment are constantly being developed. adhesives+coatings is up to date with the latest innovations and can help you find the right acid-resistant concrete coating for your application. Please do not hesitate to contact us, we will be more than willing to help you.

Contact us

Versatile automotive electronics glue and sealant

Excellent automotive and electronics glue and sealant in one

We know it’s a common problem in the ever increasingly complex challenges most industries face. How do you keep the number of adhesion failures and adhesion related workshop errors as low as possible, while also reducing the number of different adhesives and sealants you have to stock? To complicate matters, in most branches the end result must be as green as possible, recyclable or even compostable.

This might be especially true if your company produces parts or accessories for the automotive or electronics industry. The range of materials these industries use is so wide: aluminium and other metals, glass, wood, plastics, FRP. The list is endless. So, how do you hold it all together?

It’s part of the deal, you might say, to encounter issues in adhesion or sealing applications, and we’d agree. The ability to detect and find a solution for those issues in the early stages is hugely important. Some might say it can turn out to be the basic distinction between a mediocre company and an industry leader.

In general, adhesion issues may take a while to surface. The parts may already be shipped or past the assembly line of your customer, possibly resulting in warranty claims or even costly product recalls. If you’re a third-party parts or accessories manufacturer, the success of your entire company could depend on it. It’s no surprise you want to play it safe and stick to what you know.

If you are looking for an excellent bonding adhesive or sealant that can take on most materials and applications, you’re in for quite the quest. Contact us to find what you need.

The right electronics glue can make life much easier

Manufacturers will agree it’s often a bit of a balancing act. On the one hand, you need to have the best glue for the job. There are many glues that perform admirably on certain substrates, but not so well on others.

Maybe you have been looking for one that performed well on all the materials in your manufacturing process. Chances are, you couldn’t find one. The solution was to find a different glue for the other substrate combinations. So, over the years, your storage became stocked with a range of adhesives and sealants.

That may have worked for the quality of the products that roll off your production line, but we reckon the floor manager, the buyer and the stock manager may have different views on the efficiency of it all.

The floor manager will tell you that using a wide range of adhesives and sealants also increases the risk of errors on the workfloor. Most glues look pretty much the same, so it’s very easy to load the equipment with the wrong product. Mixing different adhesives in application equipment may cause unpredictable issues that lead to production downtime and costly repairs. The solution could be buying more equipment, one for every type of adhesive, but this comes with a hefty price tag.

Also, the buyer and the stock manager will have their own problems, because buying and stocking gets more complicated as the number of products in storage are increased. These problems are exacerbated by details in buying contracts, stock availability, available warehouse space, shelf life of current stock, and so on. Any reduction in the number of adhesives and sealants would be a welcome relief.

Versatile adhesives for automotive and electronics applications save money

We can think of many applications that will benefit from this. A typical application could be the assembly of air-bags or lighting units for the automotive industry. The fixation of vehicle sensors and gauges to keep them in place, while damaging vibrations are reduced, is another.

An entirely different application could be the adhesion of rfid tags to plastic substrates. Or the construction of parts that don’t require access or disassembly later on.

It is also worth mentioning that many adhesives and sealants are based on natural products, these days. We know of reliable products made with castor oil, for instance. These often don’t contain hazardous solvents, making them a modern and responsible alternative to many other adhesives.

In conclusion, when you’re assembling electronics devices for the automotive industry, or manufacture parts for any other industry for that matter, you want to reduce the number of gluesand sealants as much as possible, without surrendering adhesion strength and reliability on a wide variety of substrates and materials.

Let’s emphasize again, having an electronics adhesive that bonds easily with many materials can save a lot of time and money. The benefits are even greater when the adhesive also doubles as a reliable sealant.

If you need a specialized adhesive or sealant to replace your current product, contact us for advice.

Contact us

New thermally conductive adhesive for heat generating components

Thermally conductive 2K epoxy for heat generating parts

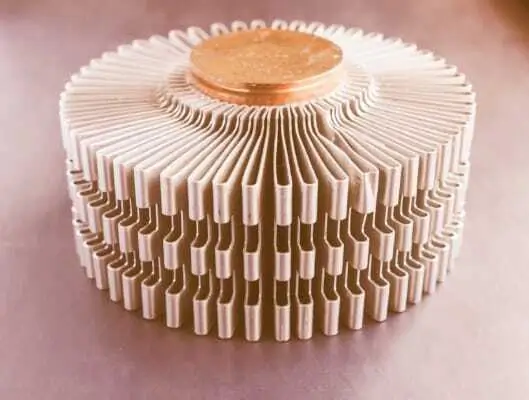

A new thermally conductive adhesive for bonding heat generating components in electronics assembly has recently been launched. This two part epoxy takes the bonding of items such as heatsink heat exchangers and LEDs up a level. Possible application methods include dual-syringes, mix-tips and automatic dispensing systems.

Technical data of the thermally conductive adhesive

This thermally conductive 2K epoxy is developed and launched by MG Chemicals. The adhesives measures 1.1W/(m. K) in thermal conductivity which works for 45 minutes. In room temperature, the curing takes place in 24 hours. However, if the temperature is raised to 65 C (149 F), the time span will be sped up to 2.5 hours.

The MG Chemical 8329TFM is a thixotropic adhesive which has good adherence to various substrates. Next to thermal conductivity, the adhesive also provides electric insulation, as well as is resistant to salt water, humidity, aliphatic hydrocarbons and mild bases. The shelf life of the smooth, grey adhesive exceeds three years.

Increasing demand in Asia-Pacific - the key factor for driving growth of adhesive film market

5% CAGR expected in adhesive film market

Manufacturing activities from many adhesive film producers are shifting to emerging economies including China, India, Indonesia, Taiwan, and the Philippines. This is due to economic reasons such as easy availability of raw materials, low transportation costs, and less-stringent government regulations. These developments are expected to result in a CAGR of close to 5% from 2019-2023 for the global adhesive films market.

Increasing demand for adhesive films

Both the growth of the packing industry and the increasing adoption of lightweight vehicles will have a positive impact on the adhesive film market and significantly contribute to its growth. Growth of the adhesive films market will be generated by the emergence of India and China as manufacturing hubs for packaging, construction, automobile, and other industries.

Also, the increasing use of adhesive films as an alternative to fasteners in automobile components, including exterior body parts, axles, and suspension systems, drives this market growth. With the adoption of adhesive films as an alternative to fasteners,

the overall weight of vehicles is significantly reduced.

Adhesive films, in general, are known for their superior strength, durability, and chemical resistance. They also determine the haptic properties, the feel of a surface.

Proper storage of epoxy adhesives supports efficiency

Proper Storage of epoxy adhesives for efficiency

Epoxy adhesives are widely used throughout industries due to their many benefits. To ensure that the adhesives retain the benefits and their functionality, it is crucial to consider the product-specific storage requirements of each system.

Storage of one and two component epoxy adhesives

When storing one and two component epoxies, the product-specific requirements must be taken into account. However, for all epoxies, the storage area must be well-ventilated. Ideal storage temperature, in turn, varies per product. For example one part epoxies are usually stored between between 5°C and 10°C (40°F and 50°F), and they must be brought to ambient temperature prior to application. 2K epoxy adhesives, for their part, are generally stored in drier areas and higher temperatures, usually between 20°C - 25°C (68°F - 77°F).

An exception is premixed 2K epoxy which must be stored frozen, in -40°C (-40°F), to let it retain its functionality for 6 months. The premixed epoxy is melted prior to application and can neither be refrozen nor reused, as it cures in room temperature.

Other factors to consider with epoxy glues

To further improve the efficiency of epoxy based adhesives, it is important to be aware of the date of manufacture, and ensure product containers are closed properly with the correct lids. Also machinery and equipment should be thoroughly cleaned between products to avoid cross-contamination. Additional attention is required when storing flammable and hazardous materials.