Single component epoxy adhesive for electronics USA

An electronics manufacturer from the USA needs a one part epoxy adhesive

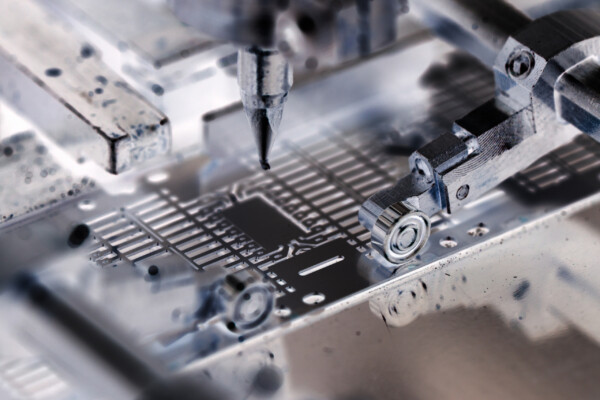

A USA based electronics manufacturer contacted us at adhesives+coatings for assistance in finding a single component epoxy adhesive for bonding two dissimilar metals in electronics. The metal to metal bond needed to be made between aluminum and nickel, preferably with a heat curing epoxy adhesive.

In order to connect this US manufacturer with the most suitable adhesive solution, we requested more information to clarify the product specifications.

Looking for an epoxy adhesive for electronics in the USA

The electronics manufacturer provided us with several criteria such as high shear and peel strength, specific curing time, as well as specified dynamic viscosity and density. Based on these specifications, we started looking for an epoxy adhesive supplier in our network.

After an extensive search we needed to conclude that none of our partners had an existing product which would suit the purpose perfectly. However, our experts contacted a metal adhesive manufacturer to enquire about possibilities for a tailor-made adhesive solution for the American manufacturer. Fortunately, epoxy adhesive formulations can be modified, and making a new glue was a challenge the supplier was willing to take on.

Custom epoxy adhesive for metal to metal bonding in electronics

In this case, the challenge was not bonding dissimilar metals, rather than finding a product that met the very specific requirements. Nevertheless, through AdhesivePlatform, the US electronics manufacturer was successfully brought in touch with an adhesive supplier, who was able to develop an adhesive formulation that resulted in the required epoxy system.

A sample of the possible solution was made, and delivered to the USA for the electronics company to carry out testing on their products. Currently, tests are being done in order to determine whether the system needs further modification.

adhesives+coatings finds the right solution for your adhesive needs

Even though it might seem that there is no adhesive solution for your application, it is always worth a try to ask around. adhesives+coatings offers a great opportunity to find a solution for almost any application: if one does not exist yet, it can be made!

Process at adhesives+coatings in 8 steps

1. Receiving enquiry

2. Collecting information and clarifying specifications

3. Looking for supplier in our database

4. Introducing the client to the potential adhesive or sealant supplier

5. Exchange of technical details between supplier and end-user

6. Sample testing and advise on system specific methods

7. Sales and delivery

8. After Sales and implementation support

What solution are you looking for?

We are specialized in the single component epoxy adhesive for electronics usa. Need the best products or advice? Then please leave your details and we will get in touch.