Pressure sensitive hot melt adhesive

Packaging industry benefits from pressure sensitive hot melt adhesive

Pressure sensitive adhesives (PSA) refer to non-reactive adhesives which form bonds of different levels. The bonding process is started by applying moderate pressure. Next to conventional solvent based, waterborne and reactive adhesives, PSA adhesives also exist as hot melt systems. The pressure sensitive hot melt adhesive (HMPSA) systems are very common throughout industries including packaging and paper.

Pressure sensitive adhesives are also known as self-adhesive systems as they form bonds when pressure is applied. In the packaging industry, tapes and films commonly make use of pressure sensitive hot melt glues. The use of these adhesives allows tapes and films to adhere to surfaces which usually are difficult to bond. For example, flexible packaging materials as well as highly varnished, coated or glossed boards benefit from HMPSA adhesives.

HMPSA for packaging tape

In the packaging industry pressure sensitive hot melt adhesives are common in manufacturing packaging tape as the specialty tapes market is growing. Using HMPSA adhesive for tape allows for neat and efficient application of the adhesive through numerous methods. It also provides the tape with beneficial properties such as fast formed permanent bonds, adherence to a wide variety of surfaces and excellent temperature performance. Below we will take a closer look at these three benefits.

1. Immediate bonding with pressure sensitive hot melt adhesive tape

Pressure sensitive hot melt adhesives exist as different types. The ones designed for high tack, self-adhesive tapes and films for the packaging industry commonly form immediate, destructive bonds. The bonding process starts once they are pressed against the surface to which they should adhere.

The fast adhering enables fast application which supports efficient processes as a larger entity. The packaging tapes that make use of HMPSA adhesive are suitable for instance for security closure construction.

2. Adhering to a wide variety of difficult-to-bond surfaces

Surfaces that have low surface energy are commonly difficult to bond. However, self-adhesive hot melt adhesives can help overcome the issues these surfaces may create. In packaging, such surfaces are rather common as they include glossy, high varnished and coated surfaces as well as flexible packaging material. Therefore, hot melt PSA adhesives are a considerable option when one wishes to bond these materials.

Share your HMPSA needs with us and get more information on possible solutions that bond perfectly with the surfaces in your process!

3. Excellent temperature performance of HMPSA adhesives for packaging

As many tape and film applications in the packaging industry involve temperature extremes and fluctuation, pressure sensitive hot melt adhesive systems have a design which promotes excellent performance regardless of the temperature. Some of the adhesive tapes are perfect for above room temperature applications whereas others are suitable for applications that take place in cold warehouses and storage areas.

Note that you should choose a self-adhesive tape based on the specific requirements of the application and service conditions.

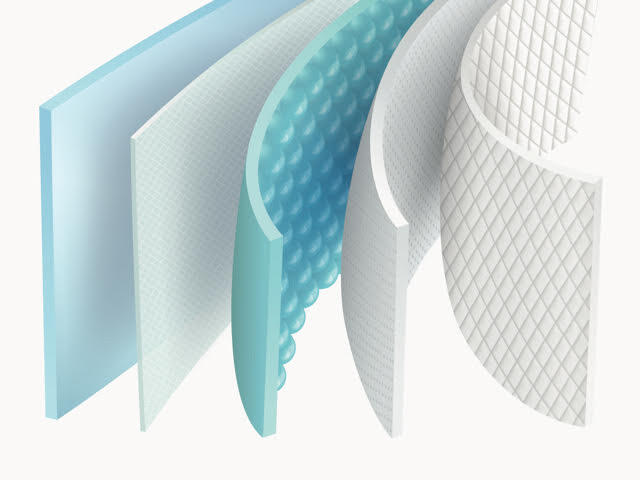

How pressure sensitive hot melt adhesive works

As we defined in the beginning of this article, pressure sensitive adhesives are self-adhesive and non-reactive forming bonds under light pressure. Hot melt adhesives, for their part, come in a solid phase, take a liquid, flowable form when heated, and solidify again when cooled down.

When these two technologies are combined to pressure sensitive hot melt adhesive systems, it is possible to use them to efficiently produce industrial tapes. The adhesive is applicable through various methods including slot die, roller or spray.

Find an HMPSA adhesive supplier

Self-adhesive hot melt adhesive systems are well-known to the packaging tapes industry and there are plenty of suppliers with many years of experience in successful bonding. Due to the multitude of suppliers and available bonding solutions, choosing the right adhesive is not always a straight-forward process. Share your HMPSA adhesive needs with us and let our experts ease the process for you by connecting you with the most suitable supplier and product.

Discover more solutions for packaging & paper

What solution are you looking for?

We are specialized in the packaging and paper. Need the best products or advice? Then please leave your details and we will get in touch.