Laminating film for paper and packaging

Laminated film for paper, foil and nylon bonding

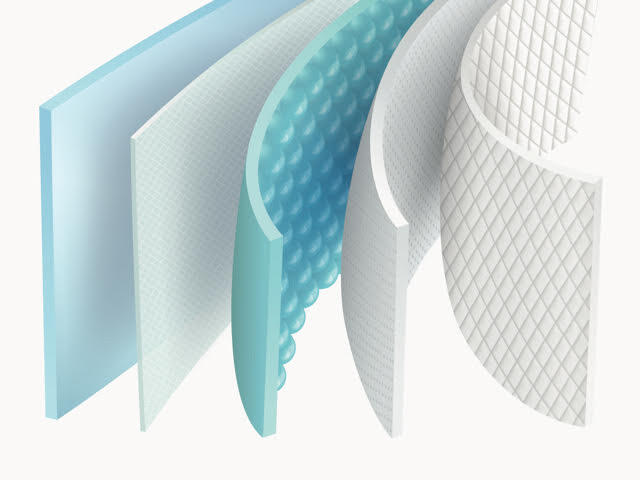

In the paper and packaging industries, laminating film is applied to surfaces such as paper, cardboard, aluminum foil and biofilm. The purpose of laminating film is to provide food and non-food packaging with barrier properties, improved appearance and haptic properties which contribute to the “feel” of a surface.

Laminating films and applications exist as numerous types. Each of them suitable for specific processes. BOPP, nylon and PET laminating film applications are the most common. The different lamination film types are generally suitable for wet bonding and thermal lamination film applications.

Lamination: how to laminate paper, meaning and film types

Adhesive lamination is the process of joining two or more flexible webs together assisted by a bonding agent, usually an adhesive. The substrates making up the webs can be paper film, biofilm or aluminum foil. The adhesive is applied to the less absorbent substrate, and the other web is pressed on it to create two layer laminate.

Lamination exists primarily as two different processes which both use special films made for them: wet lamination and thermal lamination. Here we will take a closer look at the wet lamination and thermal laminating films.

• Thermal laminating film - Dry bonding

In a thermal lamination film application (also known as hot film application) the substrate is coated with an adhesive or resin which has a low melting point. This allows the film to be applied using merely heat and pressure. Dry bonding is used in thermal lamination film application, meaning that the adhesive is activated prior to combining the substrates to be bonded

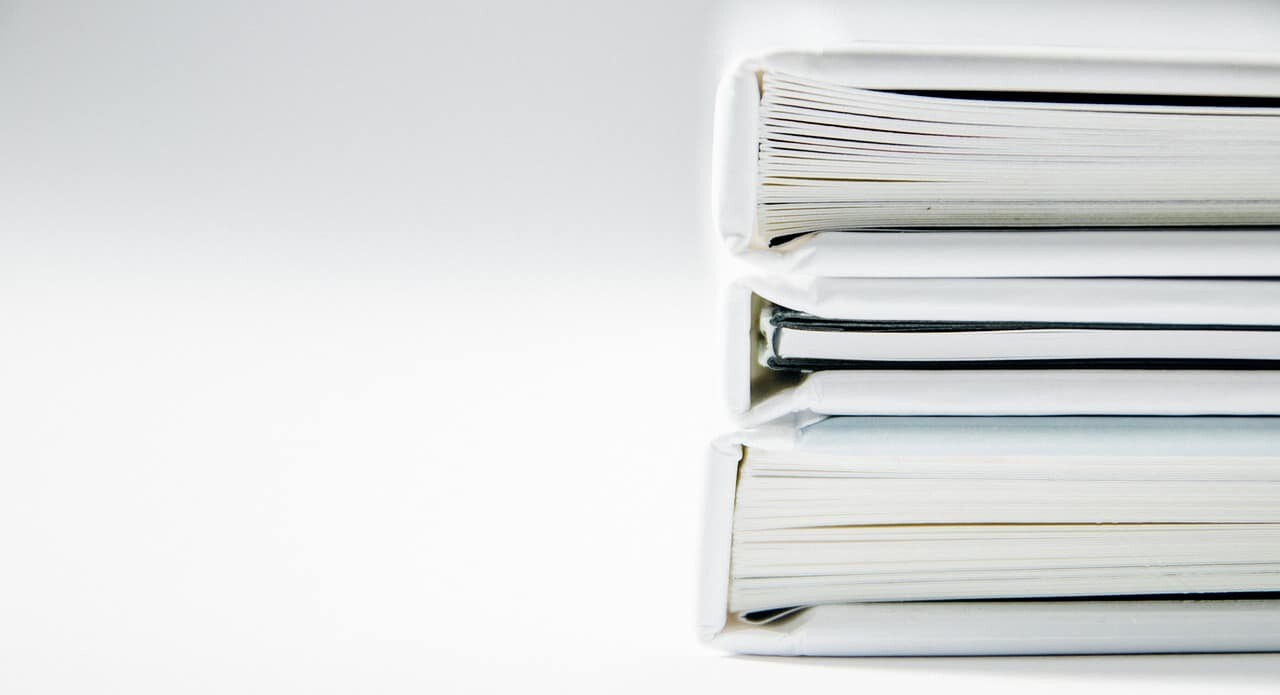

Thermal laminating films are available in different finishes, ranging from matte to high gloss depending on the material the film is made of. They exist as BOPP materials and PET films, as will be explained later on. Thermal lamination films are used for example in book lamination film applications and to laminate magazines, diaries and other printed and unprinted laminate paper products.

• Wet lamination films - Wet bonding

Wet lamination films are used for laminating two substrates, of which one is porous. Also wet lamination films exist as BOPP and PET films. The wet films are suitable for conventional lamination done with dispersion, solvent-based, UV or hotmelt adhesives. The final wet bonding takes place as the substrates are brought together and the adhesive between them is let cure.

These films often have excellent anti-static properties and they are suitable for high speed lamination. Wet laminating films are used for carton and paperboard box lamination as well as document lamination and unprinted paper and packaging.

• Wax lamination

In the wax lamination process, the bonding agent is a wax or a hot melt adhesive which is applied in a molten state to one of the substrates. As a result of the ongoing shift towards greener and recyclable packaging, biodegradable hot melt adhesives have been developed.

The wax lamination process allows for production of paper-paper and paper-aluminum foil laminating, which is common in the packaging of cookies and bakery products.

• Solventless lamination

Another response to the increased demand for more environmentally friendly packaging is provided by solventless adhesives in document lamination processes. Solventless lamination is realized with adhesives that do not contain any solvents. The solventless adhesives are usually multi component systems which curing process starts as the components react with each other.

This laminating film application allows for fast pased production as the adhesive does not require drying.

Lamination film types by lamination material

Laminating films used in the paper and packaging industries come in many types, the three most common lamination film types being: BOPP, PET and nylon. These three differ from each other when it comes to the applications, price and finish. Our experts can further help you choosing the best laminating film for your packaging!

• BOPP lamination film - Biaxially oriented polypropylene

In BOPP materials, the base material is biaxially oriented polypropylene. The lamination is realized by extrusion coating an adhesive on the film and either wet or dry bonding it to the substrate. The film has the properties of a BOPP film on wide side, and the those of the adhesive on the other.

BOPP films are available in various shades and finishes such as matte, silky satin and high gloss. The film contributes to the finished product´s looks and feel. The film creates and excellent moisture barrier which is resistant to chemicals.

• PET laminating film - Biaxially oriented polyethylene terephthalate

Another popular, yet little more expensive laminating film is based on biaxially oriented polyethylene terephthalate – PET. The PET laminating films are also known as polyester films. The PET laminating film is generally used for two-sided printing.

PET films are available as matte and gloss finishes. They are used for instance for menu cards and identification cards with magnetic strips.

• Nylon laminating film - Biaxially oriented nylon-6

Compared to BOPP and PET films, the nylon laminating films are more expensive. However, they have unique properties such as abrasion resistance and are therefore used for example for book covers and jackets. Nylon laminating film is a type of thermal lamination film applied through dry bonding.

Choose the best laminating film for your product

The lamination films are divided into groups by the process and by their base materials: BOPP, PET and Nylon laminating film. However, within these groups there are numerous different types of products which all have their special properties. Therefore, choosing the best laminating film for a specific project is not an easy job.

When choosing a laminating film, consider the following:

- Environment: the laminating film will be directly exposed to the environment in the finished product, whether it is the laminate paper cover of a book or an adhesive lamination for a package a perfume. Therefore, for example the exposure to sun, chemicals and heat should be considered.

- Ease of lamination: when it comes to ease of lamination, the thickness of the lamination material plays a great role. Thick films are often used for laminating graphics, which need to lay flat and remain so. In turn, thin films are preferred on curved and uneven surfaces.

- Quality of the film: it goes without saying that investing in good quality is costly. However, in any type of lamination, high quality is worth every penny, as a poor quality film can damage the product rather than protecting it.

- Adhesive: the adhesive of laminating film affects the appearance of the finished products. It is also the substance in direct contact with the substrate. Therefore, the adhesive should be chosen based on the desired looks and the requirements of the substrate.

Need help to find the right lamination film?

In case you are unsure which laminating film is the best for your product and process, do not hesitate to contact us. Our experts are happy to share their expertise with you, and help you find the system that benefits your product the most.

Discover more solutions for packaging & paper

What solution are you looking for?

We are specialized in the packaging and paper. Need the best products or advice? Then please leave your details and we will get in touch.