Alkali soluble labeling adhesive

Alkali soluble labeling adhesive increases PET recyclability

Different adhesives used in the packaging industry greatly contribute to the development of greener packaging solutions. Not only is it important to consider the adhesives used in packaging itself, but also the ones used in labeling. Alkali soluble labeling adhesive solutions have been developed to increase the recyclability of containers, especially PET bottles.

The alkali soluble labeling adhesive systems allow for fast and efficient removal of labels. This enables increased, fast-paced recyclability of PET bottles. The adhesive is easy to apply and strong keeping the label in place. Once the container is ready for recycling, the adhesive can be dispersed in an alkali bath, leaving little to no residue.

Important qualifications of alkali dispersible hot melt labeling adhesive

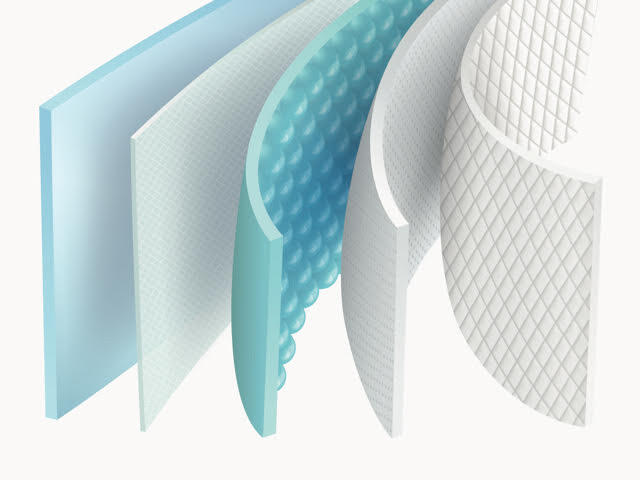

Most sustainable alkali dispersible labeling adhesives are hot melts, which means that in room temperature they appear in solid phase but become liquid once heat is applied. These adhesives are 100% solid, and do require solvents of any kind. The absence of solvents makes hot melt adhesives extremely eco-friendly.

Next to environmentally-friendliness, alkali soluble labeling adhesives should meet other requirements in order to qualify for recyclable PET bottle labeling. Meeting the strict requirements set by for instance, Returpack kft. ensures that the alkali soluble labeling adhesive supports efficient and effective recycling processes. According to these requirements, the adhesive must be soluble in alkali in 65°C (149°F). As the adhesive is alkali dispersible in a rather low temperature, the energy consumption is reduced and process sustainability is increased.

Choosing a labeling adhesive

There are different types of alkali soluble labeling adhesive systems. Choosing the most suitable for specific packaging requires considering three aspects:

- The label: the label adhesive must be suitable for bonding the label material, usually a type of plastic, although paper labels are becoming more and more common.

- The container: next to the label material, the adhesive also must be compatible with the material of the container.

- End-use environment: the environment where the product is likely to end up brings along possible performance requirements for the labeling adhesive. For example, some packaging is stored in refrigerators, and heated up in an oven, which requires temperature resistance.

Next to these aspects, the application process sets requirements for the alkali soluble labeling adhesive. Technical properties of the adhesive that should be considered include:

- Minimum application temperature: the lowest temperature in which the adhesive can be applied. A low temperature packaging adhesive should be considered if the application takes place in a cold warehouse or elsewhere in low temperature.

- Initial tack: the level of adhesion formed once the surfaces to be bonded come in touch. Low initial tack can be beneficial for some labeling applications, as it allows for moving the labels after the adhesive has applied.

- Ultimate adhesion: when the alkali dispersible adhesive is completely dry and has reached its final cure. This is important to know for further processing, storing and logistics purposes.

For more information on choosing the best labeling adhesive and suggested products, contact us! Our experts are happy to help you out.

Hot melt labeling adhesives - the most common solution for PET bottles

The most common labeling adhesive chemistries include water based and hot melt systems, the latter being the most popular. Hot melt adhesive are easy to store and apply with the right equipment and they do not require any solvents.

Furthermore, hot melt labeling adhesives exist for different application and service temperature ranges with varied chemical resistant properties. A hot melt adhesive can water or alkali soluble, which allows it to be used on recyclable PET bottles.

Interested in alkali soluble labeling adhesive?

Since many factors must be considered when choosing a labeling adhesive, it is a job involving many parties including the product manufacture, container manufacture and label producer. In case you are interested in a hot melt alkali soluble labeling adhesive, contact us! We are determined to connect you with the adhesive supplier who can provide the best possible solution.

Discover more solutions for packaging & paper

What solution are you looking for?

We are specialized in the packaging and paper. Need the best products or advice? Then please leave your details and we will get in touch.