Biodegradable resin solutions for greener production processes

Biodegradable resin solutions for greener production processes

The market asks for greener adhesives, like bio-based and biodegradable resins. Read more about how to reduce your CO2 footprint using bio-based resin solutions.

Biodegradable resin solutions for horticulture, furniture, and other industries

As the world responds to climate change, so must industry. Businesses using hot melt resins are responding with environmentally-conscious innovations. For example, for packaging, furniture, agriculture, horticulture and other industries dealing with biodegradable products, it helps for the thermoplastics and adhesives used in and around the products to be as forward-thinking as possible. Recent advances have yielded hot melt resins which are bio-based and biodegradable, and which are ideal for binding to natural fibers but which also adhere across the spectrum of substrates. Read on to learn more about new industrial solutions to growing climate-oriented challenges.

Adhesives: A shift from fossil-based traditions to bio-based innovations

Developing hot melt adhesives that are fossil based is not a crime. But it’s clear that the market for adhesives welcomes products composed of more climate-conscious, bio-based materials. While plastic in manufacturing and various industries is inevitable, the means by which plastics are engineered is experiencing a “green” transition. One cannot simply dump environmental waste into a landfill and then forget about it. Increasingly, there is a global expectation that hot melt adhesive resins must be not only strong and durable. These resins must also be biodegradable and easy to compost or otherwise repurpose. Instead of through the use of crude oil and its derivatives, new technologies can not only outperform the old, but do so with far less impact on the climate. Of course, this is easier said than done. Biodegradation literally entails microorganisms, fueled by oxygen, completely consuming a substance, water, compost and CO2, that however in quantity is equal to the CO2 the plant took up during its growth. And, as we have learned, carbon doesn’t just disappear into thin air.

Characteristics and qualities of biodegradable resins

The concept is simple: make resins from plants. The process is a bit more complicated, as bio-based resins and engineered biocomposites utilize carbohydrates in plant materials to create molecular chains of varying length and complexity. Biopolymers can be engineered according to a number of optimizations: to withstand heat, for high mechanical performance, for ductility and elasticity, etc. In short, bio-based resins are innovative compounds that are usable in conventional situations, with results that are more “green”.

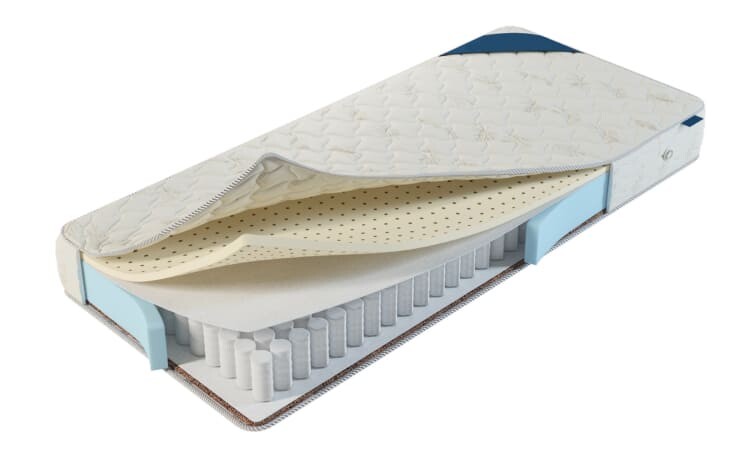

For example, an ideal bio-based resin might be engineered for the purpose of binding to natural fibers, while also being able to bind to other substrates such as metal. That same ideal resin will also have stronger adhesion to natural fibers, whereas traditional hot melt resins have more limited affinity toward natural fibers. Consider the flower vendor who wants his or her customers to know that cut flowers are bound and packaged with the most biodegradable materials possible. Consider the organic farmer who wants clients to trust that a farm is applying best practices for the lowest achievable CO2 footprint. In these cases, the horticulture industry and bio-based resins are a perfect match. Likewise, adhesive resin for furniture is a good fit, given that most if not all of the materials that make up furniture might also be biodegradable.

What to look for in biodegradable resins

It almost goes without saying that there is a difference between calling a product “bio-based” and that same product meeting specific, certifiable standards. Carbon cannot be completely eliminated, but it can be effectively limited, managed, sequestered, and counteracted. For example, ASTM D6866 is the American standard test method for determining bio-based carbon content of materials, i.e., the percentage of modern carbon present in any given product. Another standard test method, ISO 14855, evaluates the degree of ultimate aerobic biodegradability and disintegration of plastics when composted. It is difficult (but possible!) for the very best furniture, horticulture, and packaging granulate resins to be 100% bio-based and 100% biodegradable according to the aforementioned testing standards, while also achieving greater levels of sustainability and durability compared to products derived from crude oil. It is even possible for some bio-based resins to have a higher tensile modulus, greater tensile strength, and higher degree of elongation at break compared to similar crude oil adhesives.

For example, a hot melt resin can be a medium- to high-flow thermoplastic, with operational temperatures ranging from -20°C to 80°C, that can adhere to various substrates, such as natural fiber, metal, and polyester. With innovation in hot melt resins comes different measures for handling and maintenance. For example, oftentimes a bio-based hot melt comes in the form of granulates. These granulates should be melted into resin and applied at temperatures of 170-230 C. That said, the melted granulates should not be kept in a molten resin state for hours at a time, as is the case with traditional melt baths.

Contact our experts for guidance to the best bio-based resin solution for your industry

A good product is practical, affordable, and effective for the customer. An environmentally sound product does everything possible to minimize the CO2 emissions. A great biodegradable resin adhesive product achieves all of the above, while also making the transition from fossil fuels one which businesses can feel they have the knowledge to engage with.

Specifically, businesses producing and selling adhesive resins must be available for questions from customers, must listen to those customers, and apply their feedback. A recommended adhesive resin business combines the best possible materials with the highest levels of processing knowledge. That knowledge is something businesses and customers often find hard to come by. Without question, it’s a big step to take. With our expert client support, the shift from materials that are toxic to the planet to plant-based ones is not only easier, but engaging.

Together, we can help you connect with the bio-based resin producers who make the transition from carbon a success for all: customer, company, and climate.

What solution are you looking for?

We are specialized in the furniture and home. Need the best products or advice? Then please leave your details and we will get in touch.