Waterborne adhesive for mattresses

Waterborne adhesive for mattresses allows for sustainable mattress manufacturing

Lately the demand for waterborne adhesive for mattresses has been increasing as the manufacturing processes shift towards greener practices and raw materials. Waterborne adhesives are replacing their solvent based alternatives, as they do not contain any solvents, and so have very low to zero VOC (volatile organic compound) content.

Benefits of waterborne adhesive for mattresses

Next to offering a more environmentally friendly bonding solution than solventborne systems, water based mattress adhesives come with other benefits, too. These include:

- Fast application and curing: waterborne mattress adhesives are easy to handle and apply either by roller or spray. They are cured as the water evaporates either naturally or as a result of forced drying. Especially the water based spray adhesive systems can be used for automated mattress manufacturing.

- Tough and flexible bonds: water based bonds are tough and retain their flexibility. In many cases the bond is stronger than the foam layers it bonds.

- Safer working environment: as the water based adhesives for mattresses do not contain any solvents, no hazardous chemicals are released curing by evaporation.

- User-friendly products: the absence of solvents also ensures that the cured bonds do not release any possibly harmful fumes in finished products.

Changes in mattress industry affect waterborne adhesives

When waterborne adhesives for mattresses first were introduced, they only stood for a greener option compared to solvent containing systems. Today, waterborne adhesives for mattresses are just as good and durable as their alternatives, maybe even more advanced. There are several factors that have encouraged the intense development of these systems.

The mattress industry is shifting towards online sales, which increases the demand for just in time manufactured and delivered products as well as convenient and fast packaging. Water based mattress adhesives allow for fast curing bonds which remain flexible to enable roll packaging shortly after assembly.

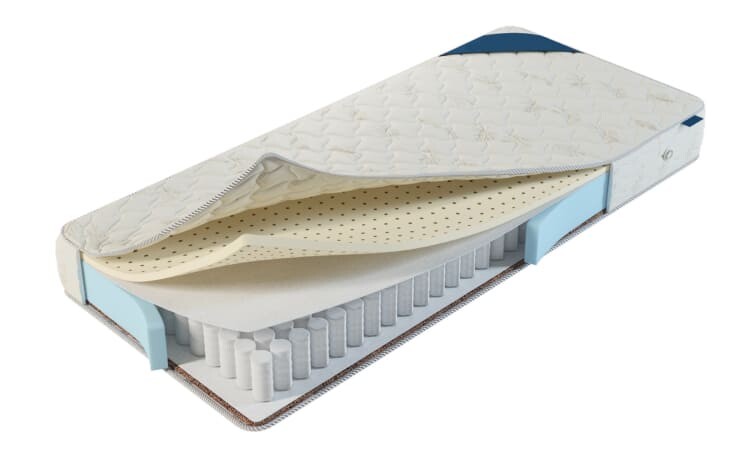

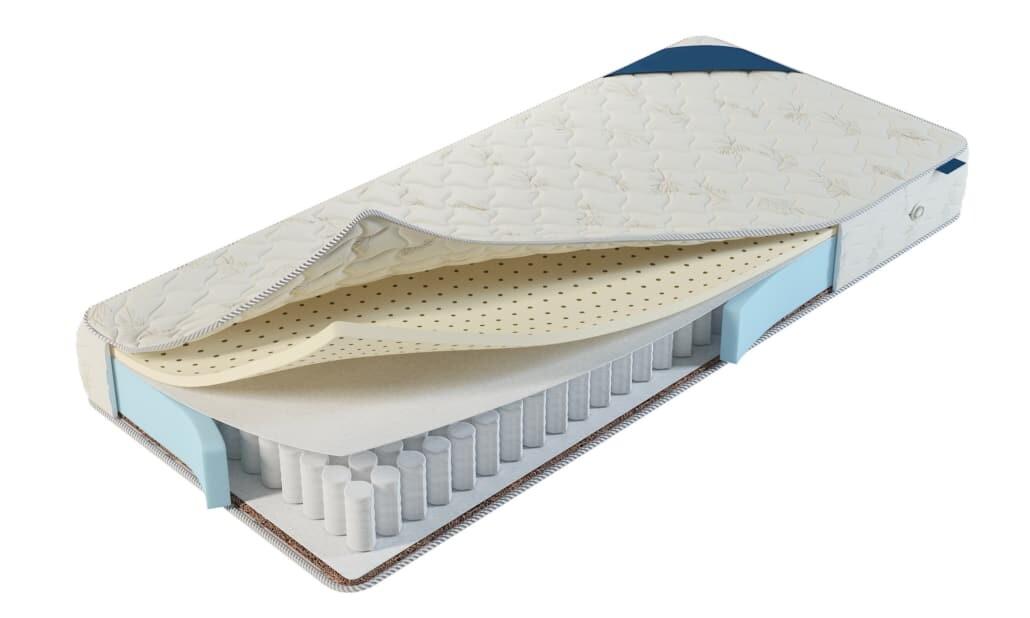

Also the range of materials used for mattresses is becoming broader. Nowadays, customers choose for comfort and they are aware of the options. Therefore, materials such as gels and memory foams have been introduced to the mattress industry. Traditionally, these materials would be difficult to glue, but the development of waterborne adhesive systems enables even the trickiest materials to be bonded.

Water based adhesive innovations for the mattress industry

The success of water based mattress adhesives has not always been self-evident. The traditional waterborne solutions were not as strong as the alternatives, they required a long time to cure and still there was a chance of mold in the packaging due to insufficient evaporation. Since then waterborne adhesive for mattresses has come a long way. Now they are considered the most important adhesives for foam bonding in mattresses, next to hot melt glues.

Below we introduce some recent innovations that make the waterborne mattress adhesives an even better choice. Get now more information on the innovations by contacting us.

1. Plug and spray portable equipment

Developed especially for low volume adhesive consumers or large production facilities in need of a remote spray station, plug and spray equipment only requires compressed air to realize industrial adhesive applications. These low investment systems bring flexibility to the mattress production and make it possible for everyone to create industrial quality bonds. Next to the mattress industry, these spray systems are also applicable for example in the furniture industry when bonding upholstery.

2. Zero overspray installations for water based spray adhesive

Waterborne adhesive for mattresses can be applied by roller or spray. The spray applications tend to result in only 35% to 50% of the water based spray adhesive ending up on the substrate. The rest is overspray. Fortunately, new spray systems have been developed to reduce the overspray and achieve even 100% transfer efficiency meaning that no adhesive is wasted and material costs are decreased.

3. High assembly tack adhesives

High assembly tack adhesives have been introduced to the market as an economical yet high performance rollable water based adhesive. High tack assembly adhesives require up to 50% less adhesive compared to other rollable adhesives. This can lead to remarkable savings in material costs compared with other mattress adhesives.

4. CR free adhesives

One of the challenges the mattress industry is facing is scarcity and increased price of CR, polychloroprene, which is an important binder used in many waterborne adhesive systems. CR free adhesive systems have been recently developed to guarantee affordable and durable adhesives. The features of CR free adhesives imitate those of conventional polychloroprene adhesives but they use another binder.

For a manufacturer it is easy to make the switch to a CR free water based adhesive. All it takes is cleaning the existing line or spraying equipment.

5. Forced curing for extra speed

Waterborne adhesives for mattresses are often considered problematic due to the long drying time they require. In order to overcome the issue, systems that are suitable for forced curing have been developed. These adhesives are easy to apply and suitable for automated mattress manufacturing. The assembly line must include an integrated forced curing step, where infrared is applied to the surface causing immediate evaporation of the water. Thanks to forced curing, water based mattress adhesives can be applied and cured in a matter of minutes. The mattress can be rolled, packed and prepared for transport immediately without risking fungus problems in the packaging. The procedure allows for just in time production and saves the manufacturer storing costs.

In need of water based mattress adhesives?

Water based mattress adhesives exist as many different formulations. Therefore, one should always consider the production process, assembly line and desired features of the finished products before choosing a system. We at adhesives+coatings are happy to help you out and bring you in touch with the industry’s leading adhesive manufacturers. All you need to do is contact us through the button below.