Biodegradable hot melt adhesive

Biodegradable hot melt adhesive systems reduce environmental impact

To respond to the increased demand for greener packaging solutions, biodegradable hot melt adhesive systems have been developed. The biodegradable hot glue systems function as a means to keep up with the needs of the clients as well as reducing the environmental impact of using adhesives in packaging. Hot melt adhesive is a type of thermoplastic adhesives which becomes liquid when they become subject to heat These adhesives are preferable solutions in many industrial applications as they do not contain any solvents. The 100% biodegradable hot glue sticks are also free of other harmful substances.

Why choose for biodegradable hot glue?

In general, hot melt adhesives appear in solid form in room temperature but, as an effect of heat, they become liquid. These 100% solid adhesives do not contain any solvents, which reduces their VOC values to close to zero.

But is hot glue biodegradable? It can be: new technologies allow for biodegradable hot melt adhesives which have the usual properties of hot melts and are compostable. Biodegradable hot glue uses materials from renewable resources. Therefore, it can be broken down by bacteria and other microorganisms.

Biodegradable hot glue systems give many manufacturers a competitive advantage, as environmental values are becoming more and more important. The use of compostable hot melt glue also reduces waste and results in savings in processing costs.

Biodegradable hot melt adhesive technologies

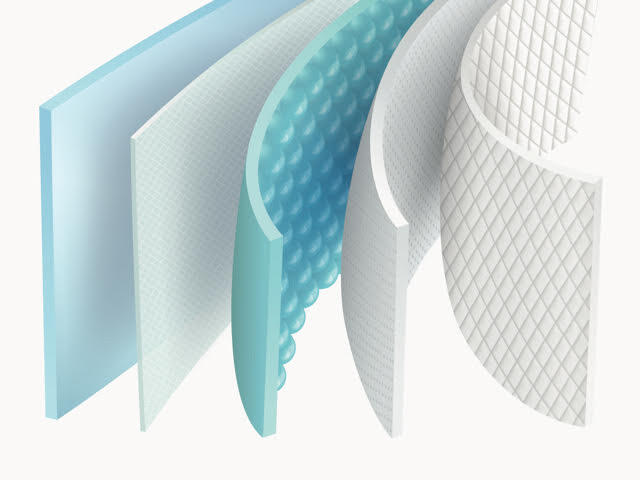

Biodegradable hot melt adhesives are common for example in packaging for take-away products, lamination for tissue paper and textiles as well as in boxes made of bio-based materials. The use of biodegradable hot glue allows for a 100% biodegradable packaging and paper products. The adhesives can be realized through several technologies which are under continuous development. Some of the currently available technologies include the following:

- Lactic acid based biodegradable hot melt adhesive: lactic acid based hot melt adhesives are 100% biodegradable and easy to modify to perfection with help of additives.

- Water soluble biodegradable hot glue: these bonding systems are practically not hot melts as they require resolving in water prior to application. The application does not require heat, which reduces the manufacturer´s electricity bill.

- Biodegradable hot melt beads: biodegradable beads behave like regular hot melt adhesive. They are applicable with hot melt glue machinery and equipment, yet they do not require heat to adhere to substrates.

As the technology improves and the need for biodegradable hot melt adhesives becomes ever-greater, there is room for new innovations. Therefore, even though it might seem there is no compostable hot melt for your application, it is always worth discovering the options. Do not hesitate to contact us for information on the biodegradable possibilities for your process and products.

Lately several new biodegradable glue systems have been developed that conform to the standard EN 13432. These include pressure sensitive tape and label adhesives as well as heat seal bonding solutions.

Biodegradable materials according to EN 13432

When opting for biodegradable hot melt adhesive systems, it might be worth checking whether the adhesive complies with the European standard for compostable materials, EN 13432 . The standard assesses materials based on four tests: biodegradation, disintegration, ecotoxicity and heavy metals.

So, when is hot glue biodegradable? According to EN 13432, an adhesive is compostable if:

- 90% of the total mass of the adhesive becomes CO2 within 180 days;

- The products of broken down adhesive can be used to enrich soil or are not harmful to plant growth in the area;

- The germination rate and plant biomass in the compost are more than 90% of those in the corresponding blank compost;

- The heavy metals in the product do not exceed the strict limits set in the standard.

Biodegradable hot melt adhesive manufacturers often claim their products are 100% biodegradable, however, the truth may be different. That is why checking for compliance with EN 13432 is often recommended. Note that even the standard does not guarantee the product is 100% biodegradable. However, it implies the product is biodegradable enough to pass the tests.

Discover biodegradable hot glue for your products and process

Biodegradability of hot melt adhesives is becoming more and more desired. Therefore, the systems are under continuous development, and new innovations are frequently brought to the market. Many manufacturers prefer to create biodegradable hot glue systems in cooperation with the end-user to ensure the best possible performance. If you are considering biodegradable hot melt adhesives for your applications, feel free to contact us for more information. We also offer help in getting in touch with hot melt glue manufacturers who are happy to provide you with the most suitable biodegradable hot melts.

Discover more solutions for packaging & paper

What solution are you looking for?

We are specialized in the packaging and paper. Need the best products or advice? Then please leave your details and we will get in touch.